FastCUT® Rectangular and Linear Optimizer

Nest rectangular and linear parts into available stock and produce optimized cutting patterns.

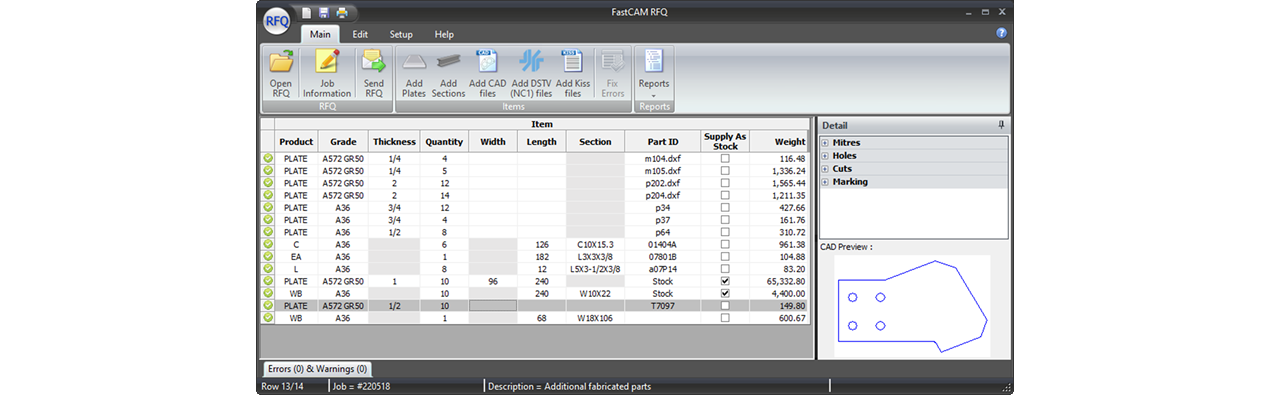

FastCAM® RFQ™

Create and submit detailed request for quote requests to steel vendors

for plate and structural sections including stock and processed parts.

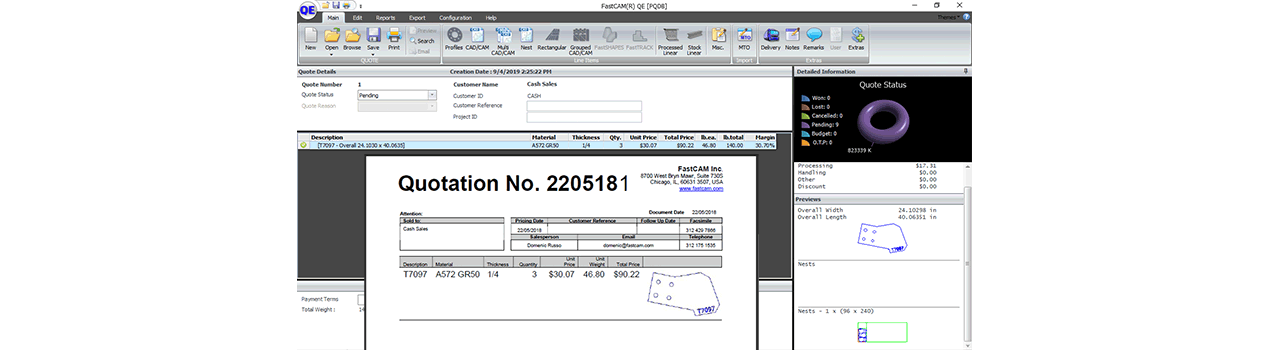

FastCAM® QE™

Create nested quotes for the supply of plate and long product parts accurately costing value added processing.

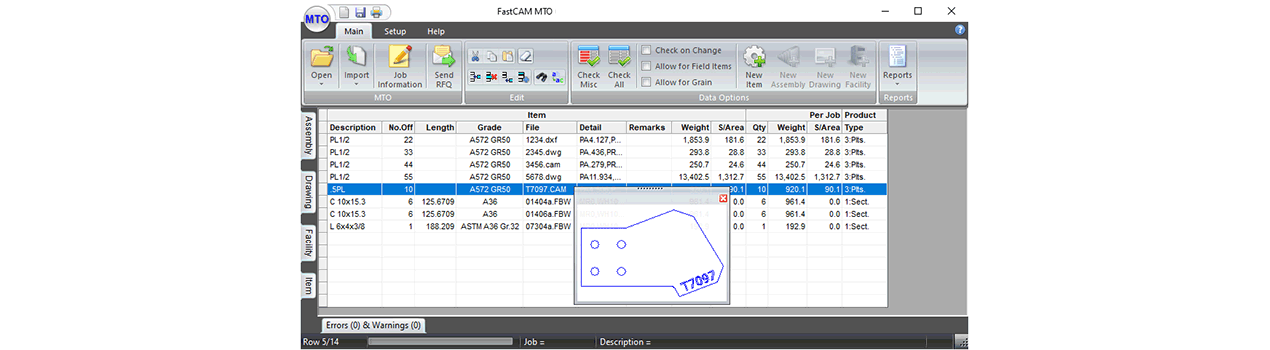

FastCAM® MTO™

FastCAM® MTO™ (Material Take Off) creates a detailed electronic RFQ file

that can be submitted to steel service centers for immediate quotation.

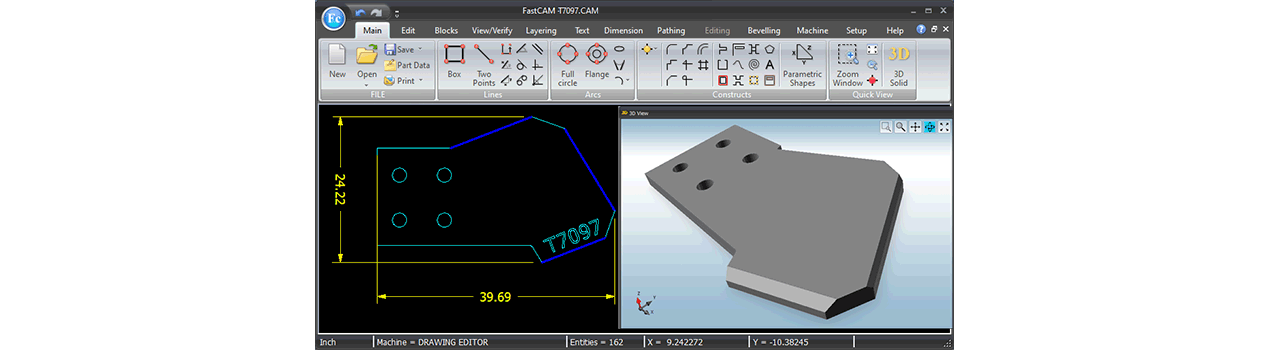

FastCAM® Drawing Editor

Create parts or view, edit and print existing CAD files, including CAM, DXF, DWG, NC1 and PDF files.

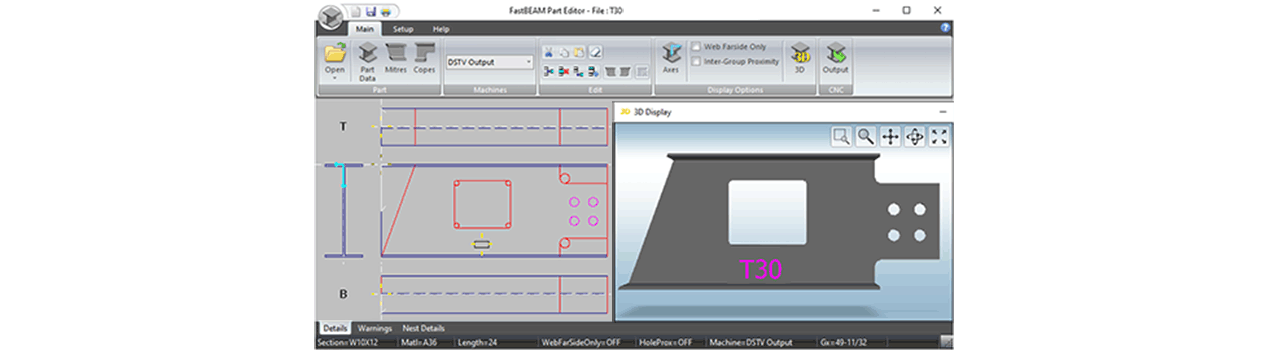

FastBEAM™ Editor

Create NC1 files for structural components such as Beams, Channels and Angles

that include cut to length, mitres, drilling and copes.

FastCAM® v9 NC System is now available

FastCAM® CAD CAM Software for Plasma, Oxy, Laser & Waterjet is a total NC solution for metal shape nesting and cutting; You can Draw, Path, Nest and Cut from the one system. FastCAM® allows people at a shop floor level to start profile cutting with the minimum of training. Affordably packaged and priced to suit your needs. Inch & Metric + multi-language support.

Cut Smarter, Quote Faster™

SSC's

Get prepared for digital, e-business and omni-channel selling. Add value but get the numbers right. Scrap must be estimated with plate and beams. Remnant must also be estimated, stored, tracked, used, sold.

Metal Fabricators

We understand the job to be done. Engineers want faster turnaround on the estimation and production of detailed cut steel components. Fabricators want fully specified electronic job files.

Heavy Industrial

From shipbuilding to infrastructure and construction, FastCAM® offers affordable alternative solutions to expensive 3D detailing systems for joining shaped plate, beams, tube, channel and pipe.

About Us

We Are

Inventors and Industry Leaders

Now in our 40th year, FastCAM started in 1976 and invented Interactive Visual Nesting and NC verification under CP/M before the IBM PC and before the mouse. Our flagship product FastCAM® is still renowned as a complete, easy, low cost offline profiling solution and the total number of OEM units for just the NC flame cutting software is now over 120,000. Over 100 flame cutting and laser machine manufacturers have packaged FastCAM® with their machines and many new partners see value in our directions.

Today, we are inventors with our own laboratory. Our current focus is on the transformative and disruptive challenges facing the steel industry, specifically value-added. Our most recent success involves part of an overall 'faster to market' business approach and addresses the cost attributed to poor quoting in the steel industry, including the need for universal standards and digital automation related to Quoting and Fabricating Cut Steel Components - plate and structural.

NC Controls

ADTECH :ATLAS ALLEN BRADLEY; ALLEN BRADLEY 2; ANCA200; ANCA2000; ANCA PLATEMATE; AUTOPATH; AUTOPILOT; BURNY 2.5/2.5R, 3, 5, 10, 1250,1400; COMPUPATH; DYNAPATH; EDGE; ESAB; ESSI; FAGOR; FANUC; FARLEY SYSTEM32; FASTCNC INFINITY; FL CNC; LINUX; LYNX; MACH3; MAZATROL; MESSER; MICROPATH; MULTICAM; MYNUC; PICOPATH; PDF 32; PROMOTION; SIEMENS; SILVERS, START SHAPHRON; UCNC; VISION 1000; VISION 2000

NC Cutting Machines

AMADA; ARCBRO; ATLAS; BOC; BOLICHANG; C&G; CR ELECTRONIQUE; CUMAQ; DYNATORCH; ECKHERT; ESAB; ESAB CROSSBOW; FANUC FABRICATOR; FARLEY; FARLEY HERCULES; HANCOCK; HARBIN WELDING & CUTTING; HONEYBEE; HYBRID; HYCUT; IWATANI; JHE; JOLUMA; KINETIC; KOIKE SANSO; KOMATSU; LASER LAB; LINDE; LIQUID ARC; MAZAK; MICRO EDGE; MESSER GREISHAM; MYNUC; PCS; PEDDIMAT; PIERCE CONTROL AUTOMATION; PROCUT; SAF; SHENZHEN BOLICHANG; STEELTAILOR; TANAKA; TAYOR; TORCHMATE; UNION CARBIDE; WHITE MARTINS; WESTINGHOUSE; ZAKMET;

Shearing & Sawing

KALTENBACH & WAGNER HDM Saws HD 911, HDM 1311, HDM 1020, HDM 1431 KBS bandsaws KBS 851DG, KDS 1001DG, KBS 1301DG. KD Drilling machines: KD603/615, KD 803/815, KD 1003/1015, KD 1203/1215, KD 2003/2015 KF Plate processing Centers KF 1006 and KF 1505.

Lasers

(most) AMADA; BYSTRONIC; CINCINATTI LASER; LASER LAB; NTC LASER; SILVERS.

Our Stats

Years in Business

OEM Partners

NC postprocessors

Systems worldwide

Data Strategy

Our premier products are designed to be open standards and compatible with all

of the popular CAD/CAM, enterprise, B2B/B2C and e-commerce formats.

Inventors

FastCAM is a very successful technical R&D and Patent based company specializing in Optimization, Computation & Automation for Industrial Cutting & Welding. We have a dedicated testing laboratory.

Digital Era

The move to the digital era forms part of our strategic vision for our products within the metal service sector, from seamless job communication to the automated quotation and production of fabricated parts.

Our Premier Product is our Quoting Solution

"Using FastCAM software, we now provide customers with more accurate, efficient and faster quoting than ever before....we can also now accept electronic files for quicker turnaround on quoting."

"FastCAM connected our quoting to real time stock and customer pricing through our ERP System (SAP). Being able to accept data from different inputs means we are able to respond so much faster, in fact up to 90% on some jobs. "

Geoff Tregoning / MIS Distribution / OneSteel

"We have come to rely on a fast, consistent method of quotation that gives us true costs. We are confident we have our quotations right. It is now an important part of our overall 'faster to market' business approach."

Brendan Keates / Manager / Central Steel

"Integrating QE with our nesting system improves quality assurance and has doubled our machine utilisation. Considering that most of our users are sales people and not engineers, we have remarkably few problems."

Neil Hawkes / Production Manager / Sandvik