FastCAM® QE™ Single User Bundle

FastCAM® QE™ is a quote OPTIMIZER for fabricated parts sold by a steel service center. For sawing, shearing and burning needs, FastCAM® QE™ will create instant quotes with accurate calculation of tonnage, remnant, scrap and all costs related to the job.

OPTIMIZED PROCESSING QUOTES

FastCAM® QE™ is a multi-user, comprehensive quote system which offers accurate, nested, optimized quotations for all processed parts with full graphics. For sawing, shearing and burning needs, FastCAM® QE™ will create quotes with accurate calculation of tonnage, remnant, scrap and all costs related to the job.

Our fast optimized steel quoting system is a proven integral part of an overall 'faster to market' business approach. The new challenge for SSCs is that sales people are being overloaded with massive amounts of calculations and a variety of complex CAD files that they often can't read or understand. The move to a digital flow of information means there is a shift of the skills base back up the line from the shop floor to the front office. Estimators and sales people need a complete quotation solution that fits all their needs and empowers them and FastCAM offers a purpose built, beginning to end 'sales centric' solution.

Automated quoting of fabricated parts!

FastCAM® QE™ empowers sales people by producing accurate, nested, optimized quotations for plate and structural processed parts without calculators, CAD/CAM or NC programmers. Sales people and estimators can handle digital quotations without spending hours re-drawing or on manual take-off.

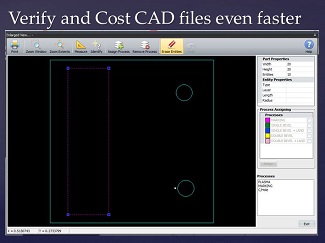

- Quote instantly from CAM, DXF, DWG, NC1 files.

- Quote instantly from the FastPART® profile shape library.

- Quote instantly from PDF files using the FastCAM® Drawing Editor as a companion program.

- Optimize quotes for profiling & shearing: parametric, true shape & rectangular.

- Optimize quotes for sawing & drilling long products: beams, channels, angles etc.

- Intelligent nesting engine separates remnant from scrap.

- Quote and re-quote in minutes ready to print, email or fax.

- Quote database with pre-defined reports for easy review of sales data.

- Empowers sales people and guarantees profitability.

- Pass winning orders to any ERP or accounting system.

- Pass job data to any NC processing system.

- Inch and Metric.

- Windows based with option to deploy in a hosted environment including Citrix or Terminal Services.

Estimates can be prepared based on accurate and fast calculations using real shop times and material costs while nesting and material optimization further improves productivity and margins. Users can simply and quickly prepare quotations for plate and structural products for all brands of burning machines, Oxy-fuel, plasma, laser or Water-jets. The software contains the FastPART® comprehensive library of common parts and sections that can be selected; basic dimensions are entered with material type, thickness and quantities. Alternatively, customer supplied DXF files can be used instantly. The laborious job of creating and costing a Bill of Materials is also automated. No more re-keying, just import and quote!

Customers can be faxed or emailed directly from the desktop and the integrated SQL database tracks all quotations. Output can even be used directly in CAM systems for processing. Quotations can be marked as won, lost or pending. The powerful reporting features are extremely useful for sales managers, production planners and estimators. Open standards design allows for the system to be integrated into upstream ERP systems and downstream to production. A solution to grow with you while providing the crucial sales, costing and profit data you need right now.

FastCAM® QE™ subscription includes FastCAM® QE™, FastCAM® Drawing Editor and FastCAM® MTO.

Testimonials

"Using FastCAM software, we now provide customers with more accurate, efficient and faster quoting than ever before....we can also now accept electronic files for quicker turnaround on quoting."

"FastCAM connected our quoting to real time stock and customer pricing through our ERP System (SAP). Being able to accept data from different inputs means we are able to respond so much faster, in fact up to 90% on some jobs. "

Geoff Tregoning / MIS Distribution / OneSteel

"We have come to rely on a fast, consistent method of quotation that gives us true costs. We are confident we have our quotations right. It is now an important part of our overall 'faster to market' business approach."

Brendan Keates / Manager / Central Steel

"Integrating QE with our nesting system improves quality assurance and has doubled our machine utilisation. Considering that most of our users are sales people and not engineers, we have remarkably few problems."

Neil Hawkes / Production Manager / Sandvik