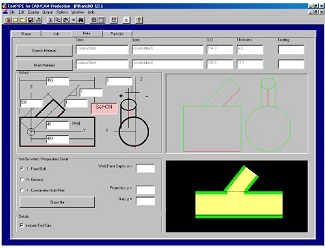

FastPIPE™

A specialist program for profiling and adding penetrations to heavy tube.

PROFILING HEAVY PIPE/TUBE

CNC pipe cutting machines are mainly used in two major areas: pipeline and space tube frame steel structures.

The pipeline application areas are mainly concentrated in the petrochemical, natural gas, shipbuilding, metallurgy, boiler / pressure vessel, power and other infrustructure industries, including long-distance pipeline, utility pipes and industrial pipes. The structural characteristics are usually single node intersects.

Parts can be developed quickly and adjusted to seam locations etc., to ensure they fit available stock.

- Automatically produces meaningful data for the forming and joining of parts when appropriate.

- Creates a detailed PartsList table which is ideal for estimation. No more guesswork!

- Produces a full length wrap around template as a pattern. If the diameter or length exceeds the capacity of the pipe cutting machine it can be created as a DXF or CAM file which can be edited in an external CAM system (or plotted).

In addition, the FastCAM® System can be used to add various details to the pattern. e.g. Slots can be added to a pipe intersection profile when reinforcing plate is to be inserted in the joint.

The system is sophisticated but uses familiar shop floor terminology making it very simple to use. To get a feel for the program you can check out our FastSHAPES playlist on FastCAM TV. The FastPIPE program is very similar in functionality. The difference is that FastSHAPES® is for pre-formed (flat) plate.

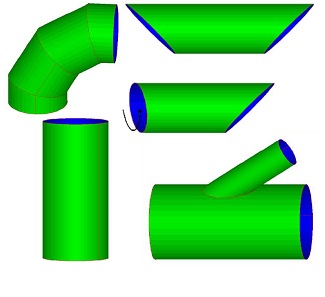

Four 'shapes' cover most pipe development needs:

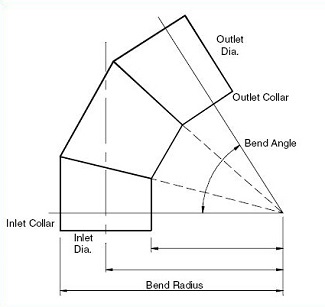

- Elbows: Transforming gored bends.

- Pipe Branches: All types including 'set-on' and set-in' developments and offset branches.

- Standard Pipes: Short square-cut stubs.

- Mitred Straights: Short square-cut stubs, complete with mitred bend(s) and twists.

Wrap around templates are produced in X,Y co-ordinates which allows for manual nesting of parts. Weld preparation is easily applied to a square-cut edge as a secondary operation (often after forming and/or removal of green). Inside/outside mark and cut line edges are also handled, as are assembly markings. Three standard weld types are accommodated: Fixed Butt (Groove) Weld; Combination, Butt-Fillet, or alternating Butt, Weld; Square cut Butt (Groove) Weld.

FastPIPE™ works as a standalone system however the program is complemented by FastFRAME®. Contact us to obtain a price for these type of specialist projects.